Time:2023-07-05 13:59:51 Share To

If you need our products,you can leave your contact informaction,our sales manager will send more information and quotation to you! Our email: sales@zxcrusher.com, WeChat/whatsapp:+8613676922906.

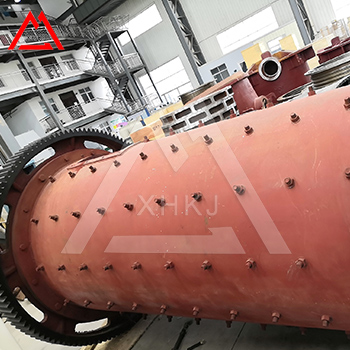

B mill is a kind of fine grinding machine widely used in industrial production. It is suitable for grinding various ores and other materials. Strong adaptability, continuous production, large crushing ratio, convenient speed regulation, and fineness of grinding products. However, can a b mill grind finer? So how to adjust the fineness? Below are the details.

1. How fine can the b mill grind?

It can grind 0.074-0.89mm, through the conversion between mesh and millimeter, that is to say, it can be ground to about 24-200 mesh.

The b mill has a hollow cylinder, which contains materials to be ground and crushed stones or heavy steel b s, and is filled with water or other liquids. When the cylinder is rotated or stirred, the materials are ground and made into crushed stones or steel b s. Roll and get crushed too. It is used as a sand making machine. Due to the fine grinding of the material, the finished product has uniform particles, full particle shape and strong adhesion. Through different grades of grinding media, the phenomenon of excessive pulverization of the product can be reduced.

2. How to adjust the fineness of the b mill?

B mills can be divided into grid type and overflow type according to different ore discharge methods, and the grinding fineness is also different, as follows.

1. Grid type

After being discharged from the gap of the grid plate at the ore discharge end, it flows out from the hollow journal.

There is a grid liner on the ore discharge side, and another grille is provided on the ore discharge end. There are many ore discharge holes on the grid, and the ground ore slurry is lifted through the grid liner to the fan-shaped chamber * to the ore discharge port. It is higher than the level of the ore discharge port to discharge the slurry.

2. Overflow type

Material escapes natur y through the hollow spigot.

The grid liner is not inst ed on the ore discharge side, but the spiral blade with the spiral direction opposite to the rotation direction of the mill is inst ed on the inner surface of the hollow journal bushing at the ore discharge end to prevent water b s or coarse ore from mixing with the slurry . The ore discharge is due to the self-flow overflow of the slurry itself is higher than the lower edge of the hollow journal bushing.

Email: sales@zxcrusher.com, Phone: 0086-371-67660555, Whatsapp/Wechat:+86-13676922906, Skype:zxcrushers@outlook.com

Please feel free to give your inquiry in the form below. We will reply you in 24 hours