INTRODUCTION

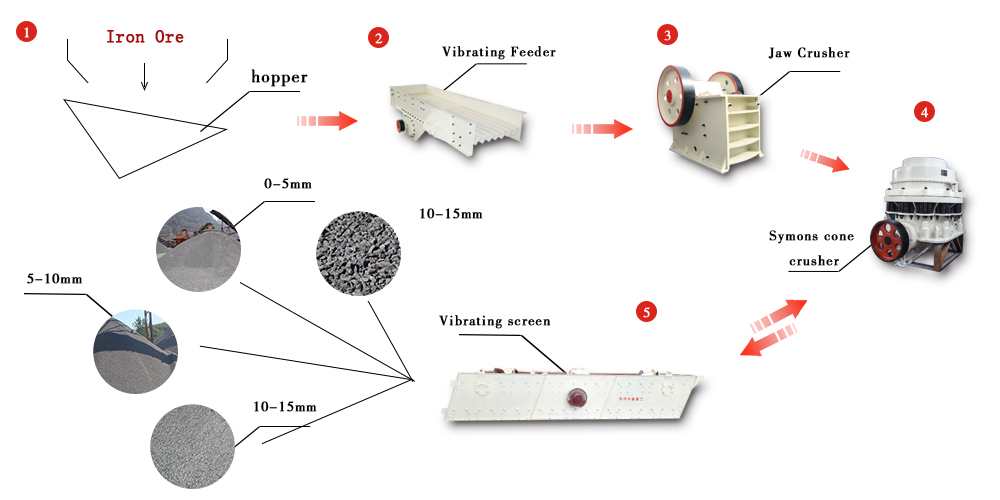

Iron Ore Dressing And Crushing Process:

According to the category and characteristic of ore, there are many different processes for iron ore dressing. In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron ore. Jaw crusher is usually used for primary crushing; cone crusher is used for secondary and tertiary crushing. Through primary crushing, and then by secondary and tertiary crushing, ore will be crushed to the suitable size for feeding ball mill.

Iron ore will be evenly conveyed by vibrating feeder to jaw crusher for primary crushing, the crushed material will be conveyed by belt conveyor to cone crusher for further crushing, material after being crushed will be conveyed to vibrating screen for screening, and material with qualified particle size will be conveyed by belt conveyor to final product pile; material with unqualified particle size will be back from vibrating screen to cone crusher for secondary and tertiary crushing, to achieve a closed circuit. Particle size of final product can be combined and graded according to the requirement of client. Iron ore beneficiation process should be as efficient, simple to the extent possible in appropriate process to achieve the effects.

Features of iron ore dressing and crushing process:

The iron ore dressing and crushing production line has the features of high automation, low operation cost, fine particle size, energy saving and environment protection. Zhongxin can provide customers with process solution and technical support, and also can design non-standard parts according to the actual installation conditions of customer.

Overview: Iron Ore Crushing ProcessIron ore crushing process crushing line is the popular in South Asia, Africa.

Overview: Iron Ore Crushing ProcessIron ore crushing process crushing line is the popular in South Asia, Africa.  Capacity:50-750 ton per hour

Capacity:50-750 ton per hour