Time:2023-03-08 14:25:44 Share To

If you need our products,you can leave your contact informaction,our sales manager will send more information and quotation to you! Our email: sales@zxcrusher.com, WeChat/whatsapp:+8613676922906.

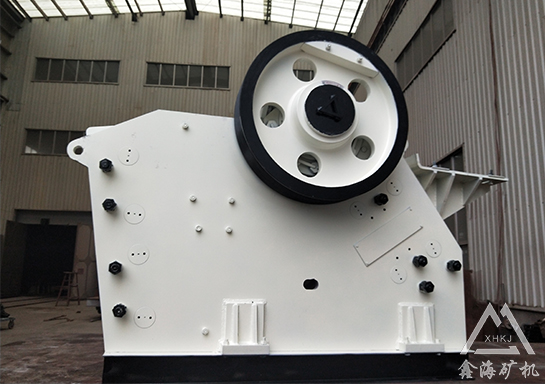

European version jaw crusher equipment selection of tooth guard plate, so its eccentric shaft and jaw plate are relatively long, so the component of the equipment is lighter after optimization, crushing strength has been ly improved. After continuous improvement and upgrading, with the same power and efficiency, the output of production has increased a lot. European jaw crusher equipment selected cylindrical pin connection, rather than welding structure, so that the European jaw is more convenient to inst and transport. The crushing chamber of the European version of the jaw is V-shaped structure, which makes the feed port adhere to the same width, and the discharge port discharge is more simple, and will not produce plugging and jumping phenomenon. As there is no dead Angle in the depth of the crushing chamber, the efficiency of crushing materials is higher.

1. Strong structure: the frame is divided into two kinds: welding type and assembly type, sm and medium-sized choose welding method, large specifications choose assembly type. Assembly method adopts modular, welding free frame structure planning, high strength and reliability, at the same time, the whole machine assembly type planning, transport, device is more convenient, suitable for underground mine, high altitude mine and other sm , difficult to transport place device.

2. Heavy duty jaw assembly durable

Heavy jaw assembly casting your heavy eccentric shaft, high quality heavy duty rolling bearing, finite element software optimization of the moving jaw body to ensure that the moving jaw assembly impact resistance and stability is high, labyrinth closure, centralized smooth system to ensure that the bearing grease is not polluted, lubrication more quickly, the use of long running time.

3. Body bearing seat

The whole cast steel bearing seat structure ensures that it matches with the frame, making the bearing run more smoothly and avoiding the unnecessary radial load on the bearing in the fastening process of the combined bearing seat.

4. Integrated motor device

The integrated device method of motor base and crusher frame saves the inst ation space of the European jaw crusher equipment. Due to the synchronous movement of the frame, motor base and motor, the adjustable motor base s the adjustment of the tension of the triangle belt, so that the life of the triangle belt is long.

5. Planning of vibration reduction device

The crusher is fixed with special rubber damping device, which absorbs the peak vibration of the equipment and ows the displacement of the crusher in vertical and longitudinal directions, thus reducing the impact force on the foundation.

Email: sales@zxcrusher.com, Phone: 0086-371-67660555, Whatsapp/Wechat:+86-13676922906, Skype:zxcrushers@outlook.com

Please feel free to give your inquiry in the form below. We will reply you in 24 hours